Fluid mechanics refers to a broad engineering field that studies the fundamental behavior of fluids, substances known to statically deform under applied shear stresses. Within this field, a number of sub-disciplines have developed. Water resources and hydraulic engineering deals primarily with flow through pipe networks, channels, and other systems that control the quantity, quality and distribution of water; aerodynamics involves the flow of air around aircraft; and gas dynamics focuses on fluids with significant variations in density, such as high-speed gas flowing through a nozzle or the flow of chemically reactive gases. The importance of understanding the mechanics of fluids is apparent from when we turn on our kitchen faucets, thus activating flow through a network of pipes and valves, to when we drive our cars, which rest on pneumatic tires, have hydraulic shock absorbers, and pump gasoline through a complex piping system. In fact, our very existence depends on fundamental principles of fluid mechanics – the flow of blood through our bodies. A number of environmental, geotechnical and structural engineering problems are intimately linked to fluid mechanics as well.

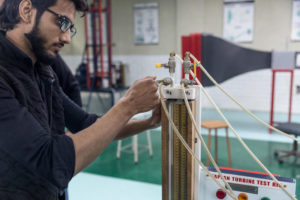

Fluid Mechanics lab is run in conjunction with the theory course Fluid Mechanics I and Fluid Mechanics II. It is an introductory course where flow behaviour, fluid forces and analysis tools are introduced. The main objective of the lab is to observe flow behavior, fluid forces and analyze it by using different apparatus and tools. The goals of the experiments include determination of forces generated when fluid flow takes place over a solid object, applications of the control volume approach, demonstration of the momentum and energy equations, viscosity measurement and engineering correlations. Intricate flow phenomena such as separations and transition to turbulence and the losses due turbulence.

Course Objectives

- To provide the students with a solid foundation in fluid flow principles

- To compare the results of analytical models introduced in lecture to the actual behaviour of real fluid flows.

- To provide practical knowledge in verification of principles of fluid flow.

- To discuss and practice standard measurement techniques of fluid mechanics and their applications.

- To impart knowledge in measuring pressure, discharge and velocity of fluid flow

- To understand Major and Minor Losses.

- To learn and practice writing technical reports.

Outcomes:

The laboratory exercises outlined here are designed to assist the student in the investigation of fluid properties, application of flow measurement techniques, determination of turbomachinery characteristics, and application of conservation laws. Students who successfully complete this course will have demonstrated an ability to

- Compare the results of analytical models introduced in a lecture to the actual behaviour of real fluid flows and draw correct and sustainable conclusions.

- Identify, name, and characterize flow patterns and regimes.

- Understand basic units of measurement, convert units, and appreciate their magnitudes.

- Utilize basic measurement techniques of fluid mechanics

- Measure fluid pressure and relate it to flow velocity

- Demonstrate a practical understanding of the various equations of Bernoulli.

- Demonstrate a practical understanding of friction losses in internal flows.

- Demonstrate the ability to write clear lab reports.

- Prove good understanding of concepts and their applications in the laboratory.

- Discuss the differences among measurement techniques, their relevance, and applications.

- Conduct experiments in pipe flow, open-channel flows and interpreting data from model studies to prototype cases, as well as documenting them in engineering reports

- Analyse a variety of practical fluid-flow devices and utilize fluid mechanics principles in design.